Maintenance and Care for Electric Scissor Lifts

Proper maintenance and care are essential for ensuring the longevity, safety, and optimal performance of electric scissor lifts. Regular upkeep not only prevents breakdowns and extends the life of the equipment but also ensures compliance with safety regulations. This guide outlines the key aspects of maintaining and caring for electric scissor lifts.

1. Daily Inspections

Conduct daily inspections before using the lift. Check for any visible damage, ensure all controls are working correctly, inspect the tires and platform, and verify that safety devices are functioning properly. Look for any signs of hydraulic or oil leaks in models that use hydraulics.

2. Battery Maintenance

Since electric scissor lifts are battery-powered, proper battery maintenance is crucial. This includes regular charging, keeping the battery clean and dry, and ensuring the connections are tight and corrosion-free. Follow the manufacturer’s guidelines for charging and storage to maximize battery life.

3. Lubrication of Moving Parts

Regular lubrication of the lift’s moving parts, such as pivot points and hinges, is necessary to ensure smooth operation. Use the recommended lubricants and follow the manufacturer’s lubrication schedule.

4. Hydraulic System Check (If Applicable)

For electric scissor lifts with hydraulic components, regularly check the hydraulic fluid level and look for leaks or damaged hoses. Change the hydraulic fluid as per the manufacturer’s recommendation.

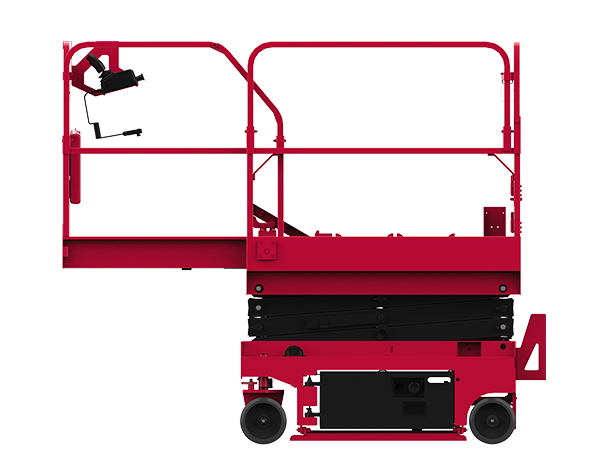

5. Platform and Guardrail Inspection

Inspect the platform and guardrails for any damage, loose components, or obstructions. Ensure that the guardrails are secure and that the platform is stable and level.

6. Control System Checks

Test all control systems, including the emergency stop button and lowering mechanism, to ensure they are in good working order. This includes both the ground and platform controls.

7. Tire Inspection and Pressure Check

Regularly inspect the tires for wear, damage, and proper inflation (if applicable). Worn or damaged tires can affect the stability and safety of the lift.

8. Cleaning and Storage

Keep the lift clean to prevent the build-up of debris that can interfere with its mechanisms. Store the lift in a dry, covered area to protect it from the elements when not in use.

9. Record Keeping

Maintain a log of all inspections, maintenance activities, and repairs. This documentation is crucial for tracking the lift’s maintenance history and for compliance purposes.

10. Professional Servicing

In addition to routine maintenance, schedule professional servicing as recommended by the manufacturer. This typically includes a comprehensive annual inspection and servicing by a qualified technician.

Conclusion

Regular maintenance and proper care are the cornerstones of ensuring that electric scissor lifts operate safely and efficiently. Adhering to a consistent maintenance schedule and addressing any issues promptly can significantly extend the lifespan of the lift and enhance workplace safety.

FAQs

1. How often should the battery in an electric scissor lift be replaced?

Battery life varies based on usage and care, but typically they need replacement every 3 to 5 years.

2. Can I perform maintenance on an electric scissor lift myself?

Basic maintenance like daily inspections and cleaning can be performed by the user, but more complex tasks should be done by qualified professionals.

3. What are the most common issues to look for during inspections?

Common issues include hydraulic leaks, battery problems, worn tires, and malfunctioning controls.

4. Is it necessary to service a lift that is rarely used?

Yes, even seldom-used lifts should be regularly inspected and serviced to ensure they remain in good working order.

5. What should I do if I find a problem during an inspection?

Address any issues immediately. If you’re unsure how to fix the problem, consult a professional technician.